AUGER FLIGHTS - SCREW CONVEYOR COMPONENTS

At Prime MFG, we offer a comprehensive selection of auger flights, including custom auger flighting, continuous screw flights, and sectional screw flights—engineered to support efficient, reliable material handling in demanding industries like agriculture, construction, drilling, food processing, and manufacturing

Our continuous screw flights feature a seamless helix for uninterrupted material flow—ideal for reducing spillage and increasing conveying efficiency. For high-wear applications, we offer continuous flights with thicker outer edges, providing extended lifespan under abrasive conditions. For balanced wear and vibration-free operation, equal thickness flights are also available.

Need something more specific? Our custom auger flighting is tailored to your operational needs—from unique pitches and diameters to material selection and surface coatings. We also manufacture sectional screw flights, allowing for variable configurations and precise assembly—ideal when diameter or pitch needs vary throughout the shaft.

Whether you’re moving powders, pellets, grains, sludge, or aggregates, our auger flights ensure optimal performance, reduced downtime, and maximum longevity.

Why Choose Auger Flights

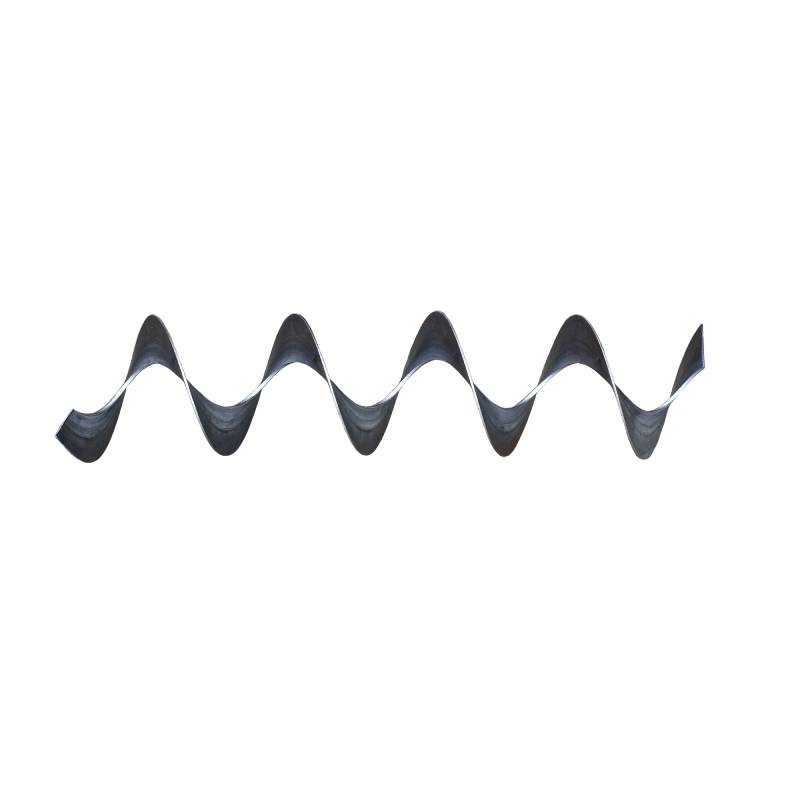

Continuous Screw Flight

A one-piece helix designed for smooth, efficient flow of bulk materials with reduced wear and downtime

Long Conveying Distance

It is suitable for long-distance conveying. A single machine can transport materials over several kilometers, and the conveying path can be flexibly adjusted as needed.

Continuous Screw Flight – Equal Thickness

Uniform flight thickness from shaft to edge ensures balanced operation and consistent performance in feeders and conveyors

Sectional Screw Flight

Individually cut and formed segments—perfect for variable pitch, ribbon flight, or custom applications

Continuous Flight Auger

Built for deep foundation drilling and piling, offering seamless, high-torque soil displacement with minimal spillage

FAQ

Auger flights are helical blades or ribbons used in screw conveyors to move bulk materials such as powders, pellets, grains, or sludge. They are an essential component of material handling systems, designed to efficiently transfer materials along a horizontal or inclined path.

- Increased Efficiency: Auger flights provide reliable and uninterrupted material flow, improving overall system performance.

- Reduced Downtime: Their design ensures that materials are moved quickly and efficiently, reducing the chances of blockages and downtime.

- Extended Lifespan: With custom options such as thicker outer edges for high-wear applications, our auger flights are designed to last longer in harsh conditions.

- Versatility: Suitable for a wide range of industries and materials, from grains to sludge and aggregates.

- The type of material being handled (e.g., powder, grain, sludge)

- The capacity and length of your conveyor system

- Whether you need customized pitch or diameter

- The abrasiveness of the material and whether you need thicker or equal-thickness flights for balanced wear

- Our team is happy to assist you in selecting the right solution for your specific needs.