Belt Conveyors

The belt material can be selected based on the characteristics of the transported material, such as heat resistance, oil resistance, and acid and alkali resistance.

Key Feature

- Long-distance conveying

BELT CONVEYOR

Find the solution that best fits your application

Belt Conveyor Manufacturer | Melbourne | Australia

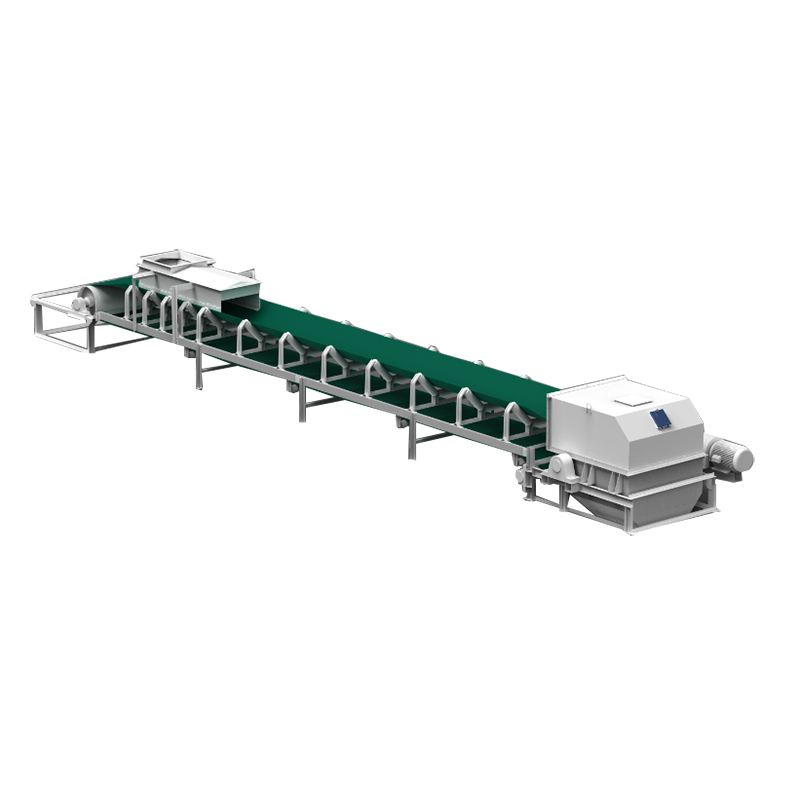

A belt conveyor is a continuous conveying device widely used in various industries. It utilizes a continuous belt as the traction and carrying component, allowing materials to be transported along horizontal or inclined directions. Its simple design, ease of operation, high efficiency, reliability, energy-saving, and environmental-friendly characteristics make it a common material handling equipment in industrial production.

Why Choose a Belt Conveyor?

- Smooth & Consistent Material Transport – Prevents product damage, ideal for delicate or irregular items.

- Customizable Designs – Available in straight, inclined, declined, or curved configurations.

- High Efficiency & Low Maintenance – Reduces labor costs and improves workflow.

- Suitable for All Industries – Used in manufacturing, warehousing, mining, food, and packaging sectors.

Efficiency and Productivity

Versatility and Adaptability

Durability and Reliability

Gallery

Prime’s belt conveyors excel in their remarkable versatility, effortlessly handling a wide array of materials, including bulk solids, loose items, and delicate or fragile products. They offer customizable configurations to meet specific application needs and accommodate diverse load capacities.

Technical Specifications

Feature | Details |

Load Capacity | 50kg – 5000kg per belt |

Belt Materials | PVC, Rubber, Modular Plastic, Steel Cord |

Speed Control | Variable Frequency Drive (VFD) |

Incline Angle | Up to 30° |

Safety Features | Emergency stops, side guards, anti-slip surfaces |

Belt Conveyors Benefits

1. Heavy-Duty Belt Construction

- Choose from rubber, PVC, modular plastic, or food-grade belts for different environments.

- Reinforced steel cord belts available for high-strength applications.

2. Customizable Configurations

- Available in flat, inclined, declined, and multi-level designs.

- Supports curved paths for optimized workflow layouts.

3. Advanced Safety Features

- Emergency stop buttons for immediate shutdown.

- Side guards and enclosed structures for operator safety.

- Anti-slip flights prevent materials from sliding back on inclined sections.

4. High-Precision Load Control

- Automated weight sensors ensure accurate material flow.

- Integrated speed control optimizes throughput efficiency.

Belt Conveyor Features

Simple Structure

The belt conveyors consists of a driving device, rollers, idlers, belt, and frame. Its simple design makes it easy to install and maintain.

Long Conveying Distance

It is suitable for long-distance conveying. A single machine can transport materials over several kilometers, and the conveying path can be flexibly adjusted as needed.

High Conveying Capacity

It can continuously transport large amounts of material, with a high throughput and efficiency, suitable for various bulk materials and packaged goods. Smooth Operation: The use of a continuous belt ensures smooth operation without vibrations, low noise, and a better working environment.

Energy-saving and Environmentally Friendly

Compared to other conveying equipment, belt conveyors have low energy consumption. They can also be equipped with enclosed structures to reduce dust and noise pollution.

Strong Adaptability

They can adapt to different working environments and conveying needs. The belt material can be selected based on the characteristics of the transported material, such as heat resistance, oil resistance, and acid and alkali resistance.

Belt conveyors are one of the most efficient and versatile material handling systems available. It is ideal for transporting bulk materials, small items, and irregularly shaped goods over long distances. Compared to other conveyor types, such as roller or chain conveyors, a belt conveyor offers:

- Smooth and consistent transport – Prevents product damage and ensures a steady flow

- Customizable configurations – Can be designed for inclined, declined, curved, or straight pathways

- High efficiency – Reduces manual labor and increases productivity.

- Versatility – Suitable for manufacturing, warehousing, logistics, mining, and food processing industries.

- Cost-effective and low maintenance – Offers a long service life with minimal upkeep.

If you need a reliable material handling solution, a belt conveyor is the perfect choice for improving efficiency and streamlining operations.

When purchasing belt conveyors in Australia, it’s essential to choose a system that meets your business requirements. Here are key factors to consider:

– Material Type & Load Capacity – Ensure the belt can support the weight and type of materials being transported.

– Belt Material – Choose from rubber, PVC, modular plastic, or food-grade belts based on the working environment.

– Operational Environment – Opt for heat-resistant, oil-resistant, or acid-Conveyor Configuration – Select from flat, inclined, or multi-level designs to match your layout.

resistant belts when necessary.

– Speed & Throughput – Determine the conveyor’s belt speed to ensure it meets production demands.

– Safety Features – Look for emergency stops, side guards, and enclosed structures to enhance workplace safety.

At Prime Manufacturing, we offer custom-built belt conveyor systems designed to maximize efficiency and durability. Contact us today to find the best solution for your business!

At Prime Manufacturing, we provide a variety of belt conveyors systems tailored to meet the needs of different industries. Whether you need a conveyor for bulk material handling, packaging, or heavy-duty applications, we have the right solution for you.

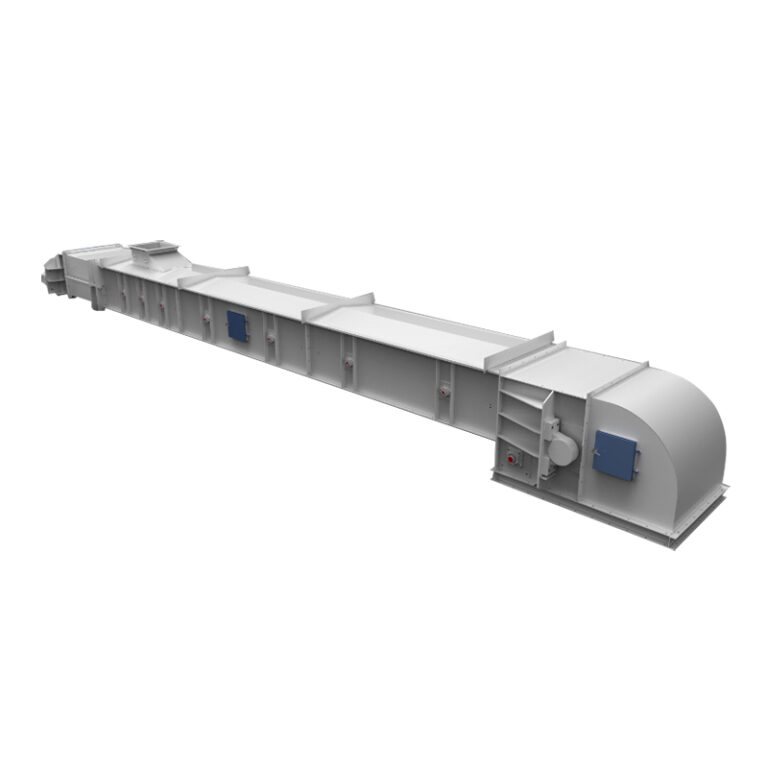

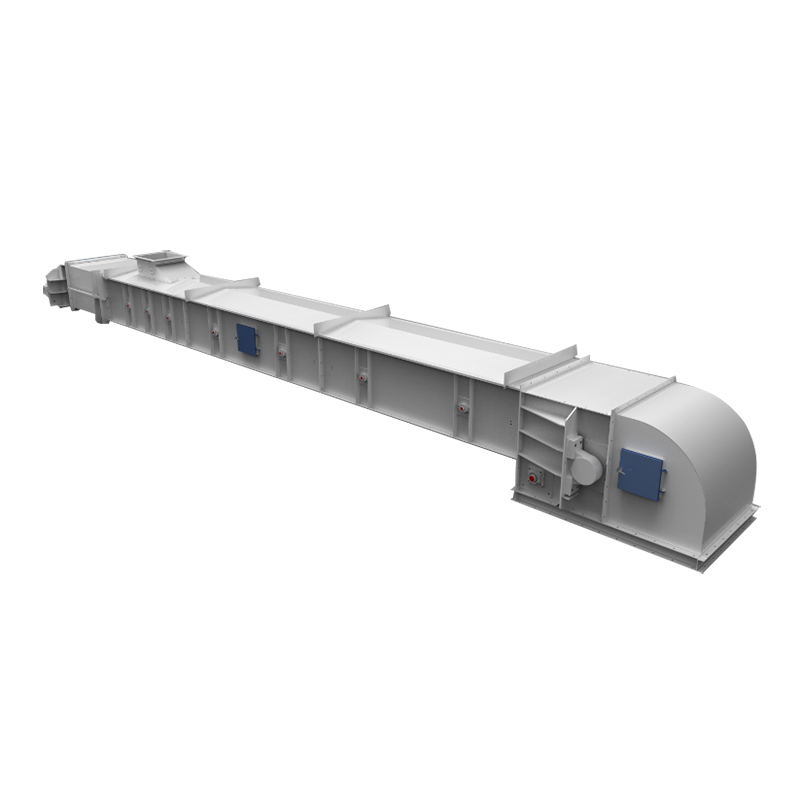

1. Drag Chain Conveyor

– Designed for handling heavy loads and bulk materials.

– Uses chain-driven paddles to move materials smoothly.

– Ideal for industries such as mining, agriculture, and manufacturing.

2. Screw Conveyor

– Perfect for transporting powders, granules, and semi-solid materials.

– Uses a rotating helical screw blade to move materials efficiently.

– Commonly used in food processing, agriculture, and wastewater treatment.