Continuous Screw Flights

Commonly used in

Industrial & Manufacturing

Consumer Packaged Goods

Food & Beverage

CONTINUOUS SCREW FLIGHTS

Find the solution that best fits your application

Our Continuous Screw Flights

Material: Carbon/Mild Steel

Features

Short production time, excellent overall rigidity and strength.

Easy to weld and assemble.

Although outer edge thickness is about 1/2 of inner edge thickness, the hardness of outer edge is almost doubled after cold rolled process there for it is much more wear-resistant than inner edge.

Gallery

Short production time, excellent overall rigidity and strength.

Easy to weld and assemble.

Although outer edge thickness is about 1/2 of inner edge thickness, the hardness of outer edge is almost doubled after cold rolled process there for it is much more wear-resistant than inner edge.

Continuous Screw Flights

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Our Product

Prime MFG’s Continuous Screw Flights are cold-rolled and precision-formed to deliver consistent material flow in a wide range of conveying and feeding applications. Ideal for handling abrasive, sticky, or free-flowing bulk materials, these screw flights are manufactured in one piece without interruption, reducing the risk of material buildup and mechanical wear. Built to fit both standard and custom screw conveyors, our continuous flights ensure durability, efficiency, and performance in challenging industrial conditions

FEATURE

- Formed as a single, continuous helix without joints or interruptions

- Ensures smooth, uniform material movement with minimal spillage

- Ideal for sticky, fine, abrasive, or semi-solid materials

- Manufactured using high-grade carbon steel or stainless steel

- Custom diameters, pitches, and thicknesses available

- Suitable for horizontal, inclined, or vertical conveying setups

- Compatible with OEM and custom screw conveyor systems

Why Choose

One-Piece Helix Construction

Continuous spiral with no welds or breaks, allowing for smooth flow and minimal product degradation

Material Versatility

Available in mild steel, stainless steel, or wear-resistant alloys to suit diverse applications

Custom Fabrication

Diameters, pitches, and thicknesses tailored to your specific conveyor dimensions and material types

Wear-Resistant Design

Engineered to withstand abrasive and high-friction materials over extended operating periods

Optimised for Flow

Ideal for sticky, viscous, or powder-based products with reduced clogging and backflow

Wide Application Range

Used in agriculture, mining, wastewater treatment, food processing, and chemical industries

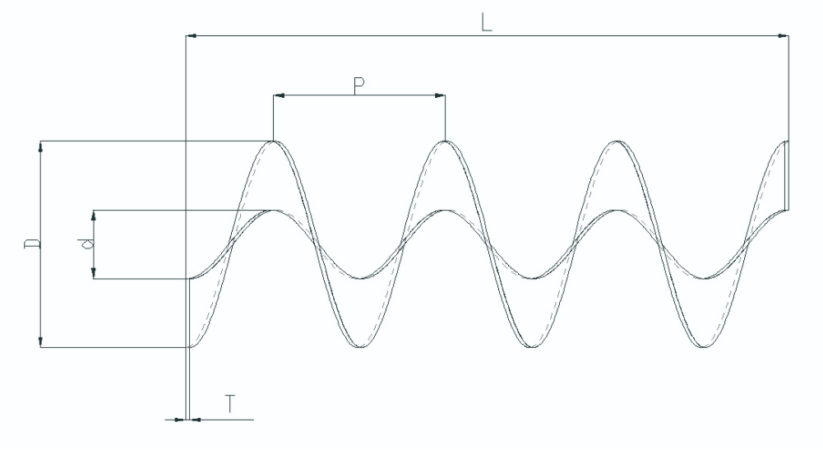

Specifications

Note: 1. The I.D. tolerance of continuous flight is within the range of customer required I.D. + 5mm, the max O.D. should not exceed three times the required I.D.

2. For all the thicknesses that are not listed above, customizations are available when reaching the minimum order quantity of raw materials.