Impact Bars

Commonly used in

Industrial & Manufacturing

Consumer Packaged Goods

Food & Beverage

Impact Bars

Find the solution that best fits your application

Our Impact Bars

Impact bar is the combination of rubber, metal frame (steel or aluminium) and UHMWPE material using a special heat vulcanization process. Low friction impacts bars are used in the conveyor loading points or transfer points to replace traditional cushion rollers. They are designed to absorb high impact loading and help eliminate spillage and scattering of the products. This results in less wear and tear on your conveyor system, dramatically improving the efficiency of the conveyor system and reducing maintenance costs.

Options:

- Normal/high Elastic Bar

- Flame Retardant Bar

Features

- Impact bars distribute evenly under the conveyor belt, therefore, absorbing the impact loading evenly to minimize the damage to the belt.

- A high elastic rubber layer absorbs maximum impact to protect the conveyor belt.

- Effectively reduce materials spillage from loading.

- Extremely low friction coefficient UHWMPE top surface significantly reduce the friction force and heat with the conveyor belt, and protect the belt for longer service life.

- “T-Slot” extruded metal frame is precisely fitted with the T-bolts along the entire impact bars.

- Also available in Fire Resistant and Anti-Static (FRAS) impact bars which complied with MDG3608, AS1334.10 and MT 113-1995 standards. Suitable for underground application.

Impact Bars

Heavy-Duty Impact Bars

Prime’s impact bars combine a high-elastic rubber core, a robust steel or aluminum base, and an ultra-low-friction UHMWPE surface. Manufactured through advanced heat vulcanization, these bars are ideal for conveyor loading and transfer points—replacing traditional cushion rollers for superior performance.

Key Benefits

Uniform Load Absorption

Chevron, herringbone, and diamond-top textures available for different load types and incline levels.

High Wear Resistance

Absorbs shocks effectively, protecting the conveyor system.

Low-Friction UHMWPE Surface

Reduces belt drag, frictional heat, and surface damage.

Precision-Fit T-Slot Frame

Secures bar firmly in place using T-bolts across its length.

Reduced Spillage

Improves material control at critical loading areas.

Compliant Options Available

Fire-Resistant and Anti-Static (FRAS) versions meet standards including MDG3608, AS1334.10, and MT 113-1995—suitable for underground mining applications.

Key Feature

Durable UHMWPE Surface: Low-friction top layer protects belt bottom and reduces wear.

Shock-Absorbing Core: High-quality rubber efficiently absorbs loading impact and vibration.

Corrosion-Resistant Aluminum Profile: Ensures easy installation and long-term structural support.

Why Choose Prime?

- Proven performance in harsh conditions

- Custom sizes and profile options available

- Quick supply and local support across Australia

- Designed for compatibility with most standard conveyor systems

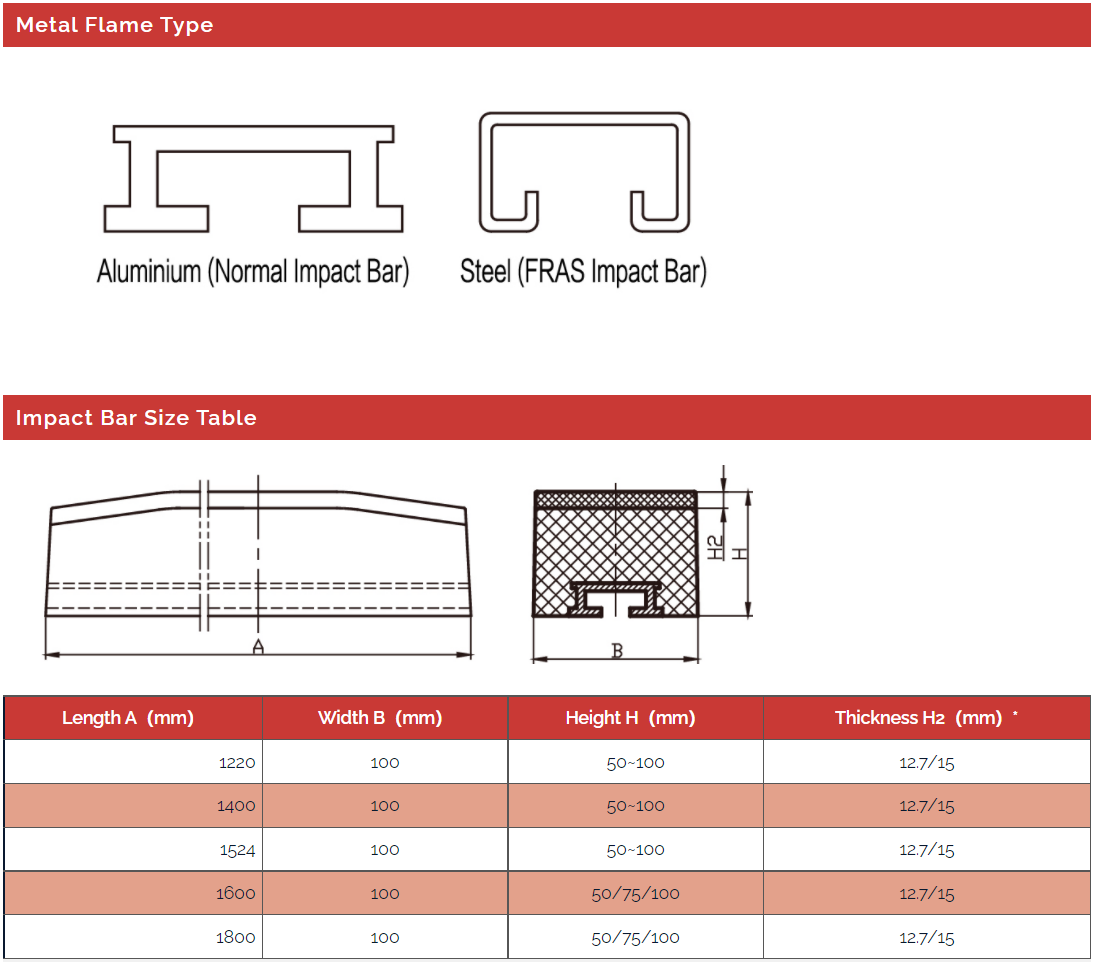

Specification