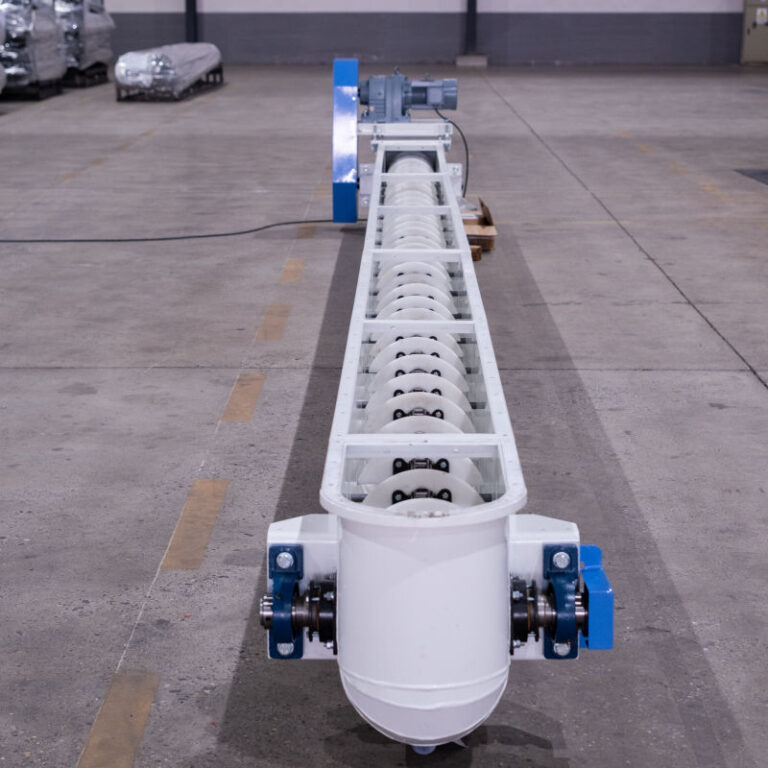

Drag Chain Conveyor

We offering timely part supplies, customized designs, and system integration.

Conveying Angle

- Horizontal, Inclined, or Vertical

Drag Material

- high-strength materials(HDPE UHMWPE, NYLON, PTFE)

DRAG CHAIN CONVEYOR

Find the solution that best fits your application

Drag Chain Conveyor Manufacturer | Melbourne | Australia

A drag chain conveyor is a device that uses a scraper chain to push bulk materials along a trough or pipe. It is widely used in industries such as mining, metallurgy, coal, and chemicals. It is primarily used for transporting bulk materials like coal, ore, sand, and grain, efficiently and reliably completing tasks involving horizontal, inclined, or vertical conveying

Gallery

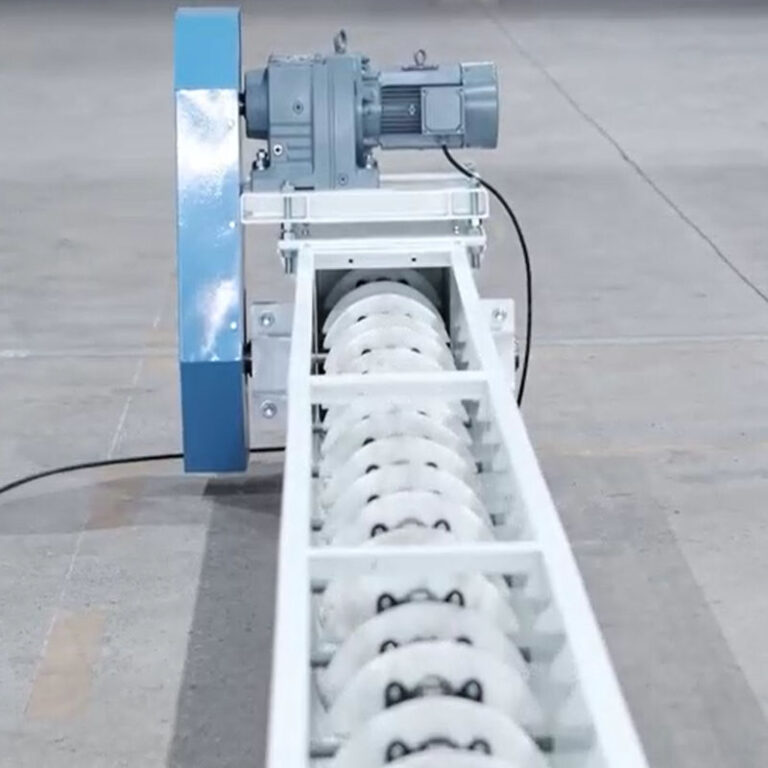

Drag Chain Conveyor Features

Robust Construction

Made from high strength materials, the scraper conveyor can withstand heavy loads and harsh working environments, suitable for long-term, high-intensity continuous operation.

High Conveying Efficiency

Capable of efficiently transporting large amounts of bulk materials, with fast conveying speeds and high production efficiency.

Wide Application

Suitable for horizontal, inclined, and even vertical conveying, with strong adaptability and a wide range of applications.

Low Material Spillage

The enclosed design helps prevent material spillage during transportation, reducing dust pollution.

Customizable Design

The scraper conveyor can be customized according to the specific material characteristics and operational requirements to meet different production needs. Easy Maintenance: The rational struct

Easy Maintenance

The rational structural design facilitates easy installation and maintenance, reducing downtime and improving equipment utilization.