Z/C TYPE BUCKET ELEVATOR

Multi-Dimensional Transport Paths: Ideal for compact factory layouts or multi-dimensional material transport without intermediate conversion equipment

Key Features

- multiple discharge points

Max capacity

- 10m³/h to 66m³/h

Z/C TYPE BUCKET ELEVATOR

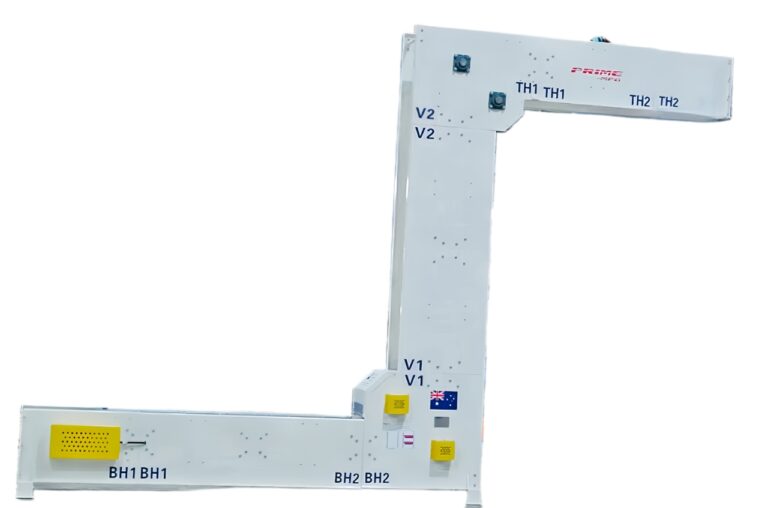

Prime’s Z (C) Type Bucket Elevator is a flexible, efficient material handling device suitable for various materials, optimizing material transport and processing in factories.

Applicable Materials:

Grains, cereals, beans, nuts, seeds, candies, food products, snacks, industrial products, and various bulk or powdered materials.

System engineered

We provide customized equipment design and system centralized automation design according to customer needs

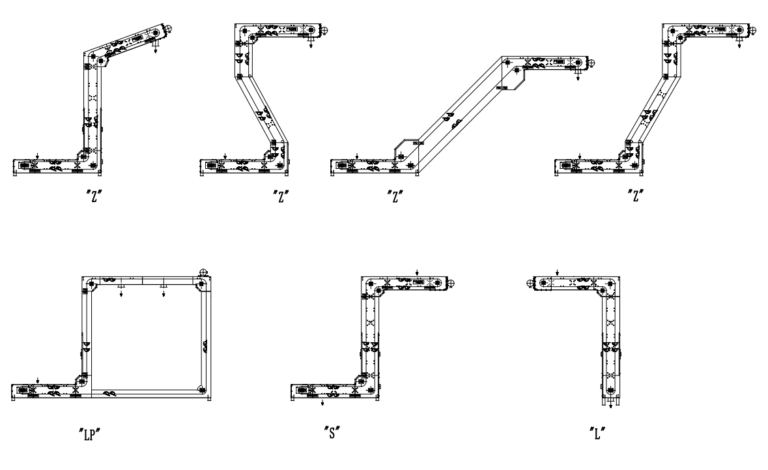

A Variety of Bucket Configurations

Offers a diverse range of bucket configurations, allowing for optimal customisation to suit specific material handling requirements.

Local maintenance team

We provide timely and effective local technical and after-sales service

Gallery

Regular Bucket Elevator Features

Multi-Dimensional Transport Paths

Ideal for compact factory layouts or multi-dimensional material transport without intermediate conversion equipment.

Damage-Free Handling

Materials are gently loaded and unloaded by free fall, preserving integrity.

No Spillage

Ensures no spillage during loading and unloading, preventing waste and contamination.

Clean Discharge

Ensures complete unloading with no residue left behind.

Wash-Down Design

Easy to clean, preventing dust and debris accumulation, ideal for food processing and pharmaceutical industries.

Multi-Point Discharge

Allows for multiple discharge points, enabling tailored distribution of materials as needed

Specifications

Available in capacities ranging from 10m³/h to 66m³/h to meet different transport needs.

Body Material

Carbon steel, stainless steel.

Surface Coating

Painting, powder coating, hot-dip galvanizing. Bucket Material: PP, Nylon, stainless steel.

Torque Limiter

Prevents overload, ensuring safer operation. Low Maintenance and Low Noise: Offers low maintenance costs and quiet operation.

Customization and System Integration

Provides personalized and integrated system design based on specific needs. The company provides timely supply of wear parts and technical support through its systematic production base and Melbourne storage and processing centre.