Regular

Bucket

Elevator

Transportation of Bulk Material

We offering timely part supplies, customized designs, and system integration.

Bucket Size

- 500 SPECs across 17 bucket types

Max capacity

- 5-2000 t/hour

Our Regular Bucket Elevators

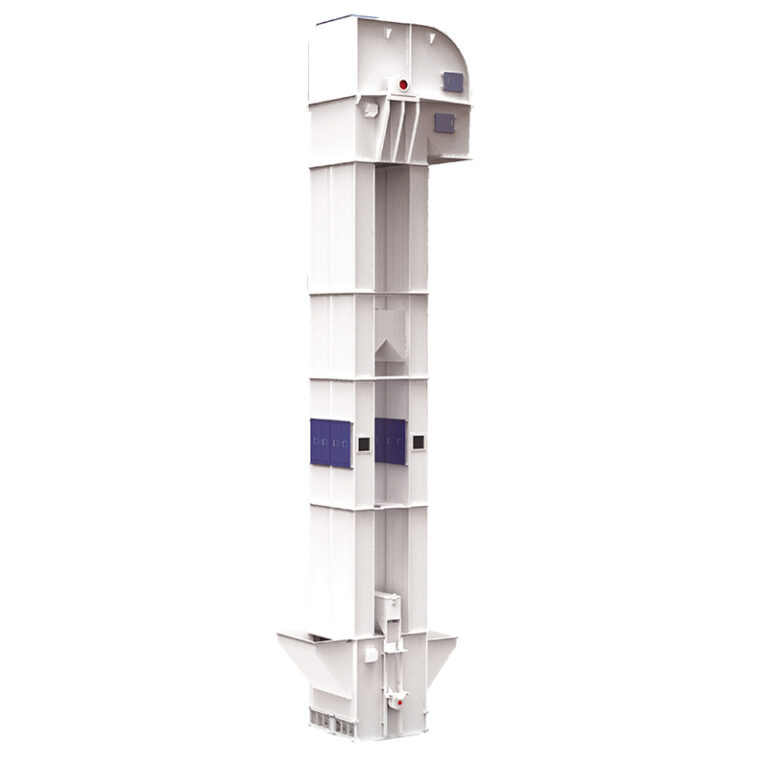

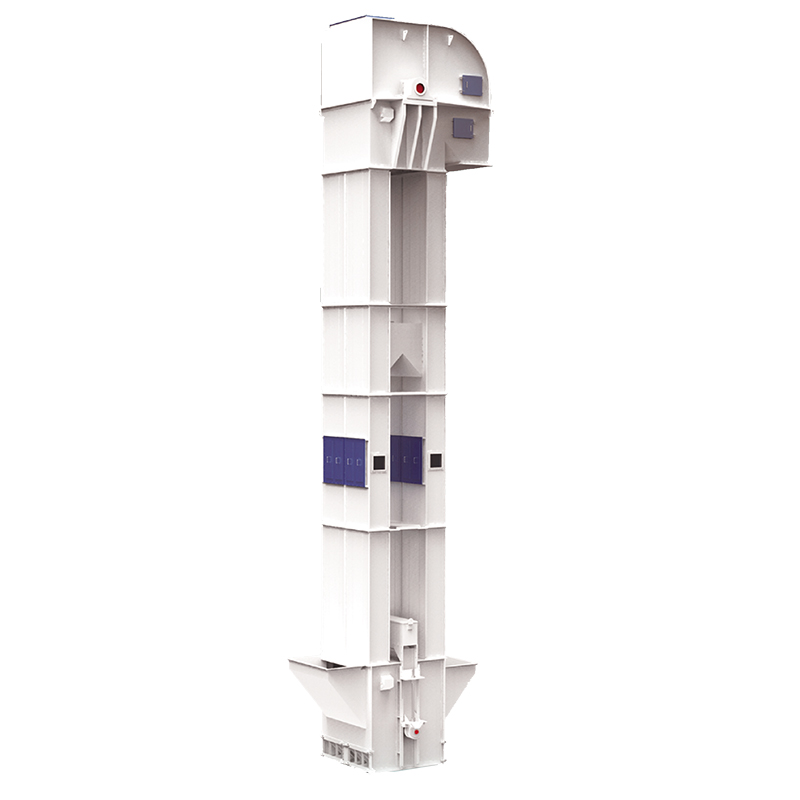

Conventional Bucket Elevator:

The bucket elevator is the most economical way to lift and transport bulk materials. It smoothly distributes materials through the discharge outlet or chute, suitable for various industrial and agricultural applications.

Applicable Materials: From light to heavy, from fine to semi-solid materials, such as grains, food, sugar, salt, chemicals, sand, and mineral products.

Lifting Capacity: 5 tons to 2000 tons/hour;

Adaptability: Available in 500 specifications, with 17 types of buckets to meet different material handling requirements;

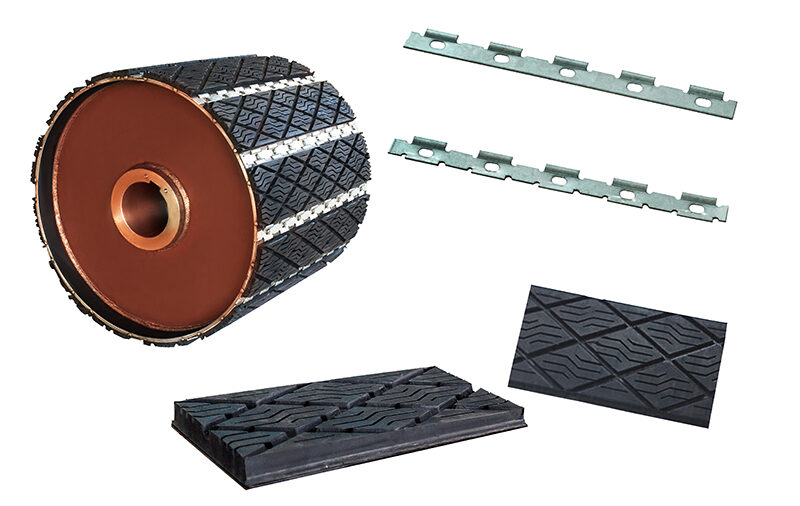

Drive Pulley: Pulley Slide Lagging, which reduces belt slippage and is easy to maintain; thermal vulcanized rubber coating is also optional;

Body Material: Carbon steel, stainless steel;

Surface Coating: Painting, powder coating, hot-dip galvanizing;

Bucket Material: HDPE, PU, Nylon, carbon steel, wear-resistant steel, stainless steel;

Elevator Belt: Optional rubber or PVC belts, with flame retardant, anti-static, oil-resistant, and high-temperature resistant options;

Sensors: Optional sensors for belt misalignment, belt speed, bearing temperature, and discharge outlet blockage.

The company has a production base for common system accessories and a storage and processing center located in Melbourne, providing timely supply of complete wear parts. Customized and system integration design are available.The company has a production base for common system accessories and a storage and processing center located in Melbourne, providing timely supply of complete wear parts.

Customized design and system integration design are available.

Gallery

Regular Bucket Elevator Features

Body Material

Carbon steel, stainless steel

Surface Coating

Painting, powder coating, hot-dip galvanizing

Elevator Belt

Optional rubber or PVC belts, with flame retardant, anti-static, oil-resistant, and high-temperature resistant options

Bucket Material

HDPE, PU, Nylon, carbon steel, wear-resistant steel, stainless steel

Sensors

Optional sensors for belt misalignment, belt speed, bearing temperature, and discharge outlet blockage

Drive Pulley

Pulley Slide Lagging, which reduces belt slippage and is easy to maintain; thermal vulcanized rubber coating is also optional;

Elevator Buckets

The buckets used in the bucket elevator are designed to be sturdy and reliable. They come in a variety of shapes, sizes and materials to suit different applications. Also, they can be customised according to the customer’s needs.

Bucket Bolt Sets

Bucket bolt sets are used to secure the buckets to the elevator belt. They come in a variety of sizes and materials, so that they can be used for different applications. Also, the installation of bucket bolt sets is simple and easy.

Elevator Belts

The elevator belt is the most important component of a bucket elevator. It is designed to be strong and reliable, and it comes in a variety of sizes and materials so that it can handle different types of materials.

Belt Fasteners

Belt fasteners are used to secure the elevator belt to the frame. They come in a variety of sizes and materials, so that they can be used for different applications. Also, the installation of belt fasteners is simple and easy.

Pulley Slide Lagging

The pulley slide lagging is designed to reduce friction between the bucket elevator buckets and the drive belt. It also helps reduce wear on the pulleys, which can extend the life of the system. It is made from robust materials for durability. Also, it is available in a variety of sizes and materials.