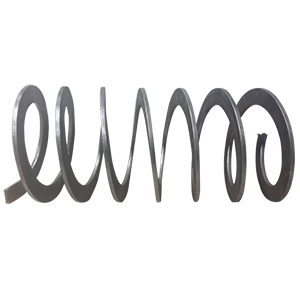

Continuous Equal Thickness Screw

Commonly used in

Industrial & Manufacturing

Consumer Packaged Goods

Food & Beverage

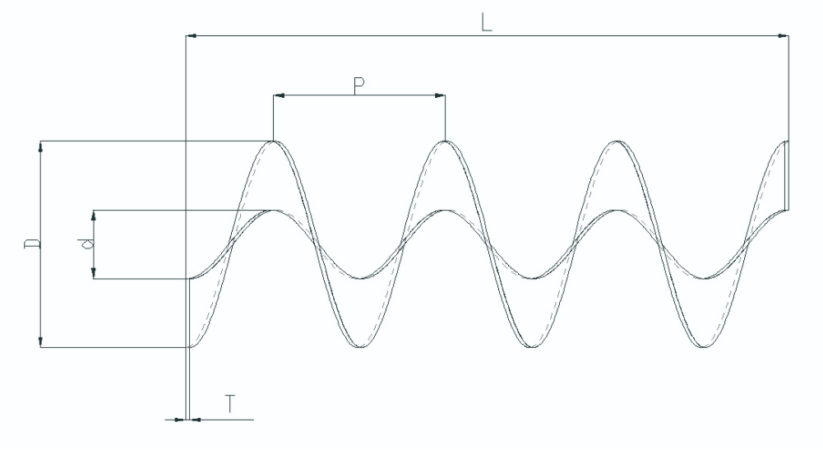

CONTINUOUS EQUAL THICKNESS SCREW FLIGHTS

Find the solution that best fits your application

Our Continuous Equal Thickness Screw Flights

Material: Carbon/Mild Steel, Alloy Steel, Stainless Steel.

Features

- Patented process developed by Prime that overcomes issues, such as forming difficulties and high material wastage for small lot production when OD/Pitch Ratio is less than 0.5.

- The forming method of continuous equal thickness screw flights is the same as continuous cold-rolled flights, whereas the thickness is consistent throughout the inner edge and outer edge.

- High precision manufacturing process.

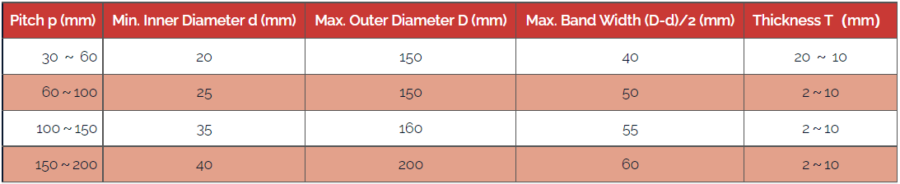

Gallery

- Patented process developed by Prime that overcomes issues, such as forming difficulties and high material wastage for small lot production when OD/Pitch Ratio is less than 0.5.

- The forming method of continuous equal thickness screw flights is the same as continuous cold-rolled flights, whereas the thickness is consistent throughout the inner edge and outer edge.

- High precision manufacturing process.

Continuous Equal Thickness Screw Flights

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Our Product

Prime MFG’s Continuous Equal Thickness Screw Flights are cold-formed with uniform thickness across the entire blade, offering balanced strength and smooth material flow. These flights are ideal for conveying systems that require consistent throughput and even wear distribution. Used in agriculture, wastewater, food, mining, and chemical industries, they ensure reliable performance and reduced maintenance over time. Our flights are compatible with a variety of shaft sizes, materials, and pitch configurations.

FEATURE

- Uniform thickness across the entire flight for balanced strength and wear

- Formed as a single, continuous helix to ensure consistent material movement

- Reduced build-up and friction due to smooth, even surface

- Available in stainless steel, mild steel, and wear-resistant alloys

- Customizable in pitch, diameter, thickness, and shaft fit

- Ideal for conveyors, feeders, mixers, and industrial augers

- Suitable for both horizontal and inclined conveying applications

Why Choose

Equal Blade Thickness

Uniform thickness from shaft to edge improves strength consistency and balanced wear in conveying systems

Cold-Rolled Helical Forming

One-piece continuous spiral ensures smooth, uninterrupted flow and precise material handling

Custom Dimensions

Available in various outer diameters, pitches, thicknesses, and shaft sizes to meet system-specific needs

Material Options

Choose from carbon steel, stainless steel, or hardened alloys based on wear resistance and application type

Versatile Applications

Used in industries like food, wastewater, agriculture, chemicals, and powder handling systems

Improved System Balance

Uniform blade profile reduces vibration and increases lifespan of bearings and drives.

Specifications