Prime’s bulk storage facilities are a testament to their commitment to excellence in storage solutions. Featuring a range of options including bolted silos, sealed silos,...

Read More

Regular

Bucket

Transportation of Bulk Material

Commonly used in

Industrial & Manufacturing

Consumer Packaged Goods

Food & Beverage

Bucket width

- 9" | 15" | 2'5"

Max capacity

- 1,800 (cubic feet/hr)

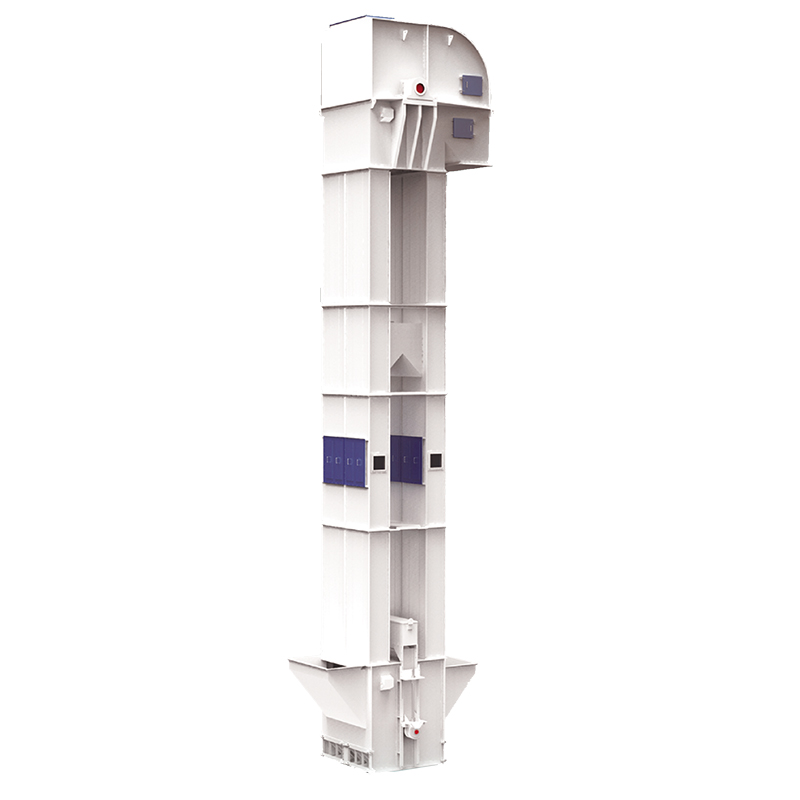

Bucket Elevators

Find the solution that best fits your application

Bucket Elevator Manufacturer | Melbourne | Australia

Packing and Weighing System

Prime’s is a trusted provider of high-quality packing and weighing systems for various industries. Built with precision and durability, these systems ensure accurate and reliable...

Read MoreConveying Systems

When it comes to efficient material handling, Prime’s Conveying Systems stands out as a trusted name in the industry. With a commitment to delivering high-quality...

Read MoreOur Bucket Elevators

Bucket elevators are the most economical way to lift and transport bulk materials. They distribute materials smoothly through discharge ports or chutes and are suitable for various industrial and agricultural applications.

Specifications and Lifting Capacity:

There are 17 different types of elevator series designed to meet various lifting and material requirements, covering almost all forms of bucket elevators. Over 500 capacity specifications are available, ranging from 2t/h to 2000t/h.

Applicable Materials:

Suitable for materials ranging from light to heavy, and from powdery to lumpy, such as grains, food, sugar, salt, chemicals, sand, minerals, and industrial products.

Bucket Transmission Methods:

Belt drive, chain drive, and Rubber and plastic chain drive are available for different types of elevators.

Equipment Metal Material and Surface Coating:

Options include carbon steel and stainless steel, with finishes such as paint, powder coating, and hot-dip galvanizing.

Lifting Belts:

Available in rubber, PVC, and PU, with options for flame retardant, anti-static, oil-resistant, and high-temperature resistant properties based on the material and operating environment requirements.

Bucket Materials:

HDPE, nylon, PU, carbon steel, wear-resistant steel, and stainless steel.

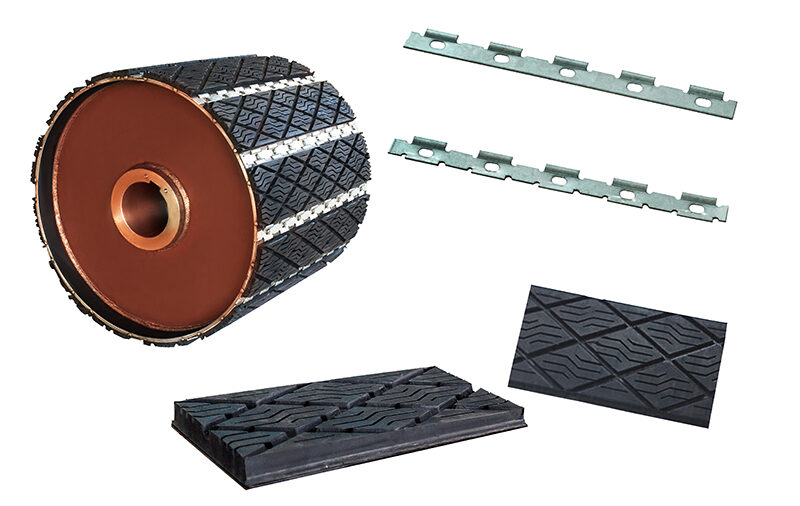

Drive Pulley:

Sliding rubber-coated pulleys to reduce belt slippage and ease maintenance; thermal vulcanized rubber coatings are also available.

Sensors:

Optional sensors for belt misalignment, operating speed, bearing temperature, and discharge clogging.

Personalized and system integration designs are available according to customer requirements.

The company has a systematic production base for common accessories and a storage and processing center in Melbourne, providing timely supply of wear parts and technical support.

System engineered to fit specific customer requirement

Local stored self-manufacatured quick-wear parts to ensure your operation

Local maintenance team to provide support 24/7

Bucket Elevator Components and Parts

Elevator Buckets

The buckets used in the bucket elevator are designed to be sturdy and reliable. They come in a variety of shapes, sizes and materials to suit different applications. Also, they can be customised according to the customer’s needs.

Bucket Bolt Sets

Bucket bolt sets are used to secure the buckets to the elevator belt. They come in a variety of sizes and materials, so that they can be used for different applications. Also, the installation of bucket bolt sets is simple and easy.

Elevator Belts

The elevator belt is the most important component of a bucket elevator. It is designed to be strong and reliable, and it comes in a variety of sizes and materials so that it can handle different types of materials.

Belt Fasteners

Belt fasteners are used to secure the elevator belt to the frame. They come in a variety of sizes and materials, so that they can be used for different applications. Also, the installation of belt fasteners is simple and easy.

Pulley Slide Lagging

The pulley slide lagging is designed to reduce friction between the bucket elevator buckets and the drive belt. It also helps reduce wear on the pulleys, which can extend the life of the system. It is made from robust materials for durability. Also, it is available in a variety of sizes and materials.

Bucket Elevator Features

Head pulley

The head pulley is designed to drive the bucket elevator and ensure that it operates at optimal efficiency. It is also equipped with a tensioning mechanism, which enables easy adjustment of the chain or belt tension. Also, it is made from robust materials for durability.

Buckets

These buckets are made from high-quality materials to ensure reliability and longevity. They are sized according to the material being transported, so that they can handle different types of materials without any issues. Also, the buckets are designed with special features such as drainage holes to ensure proper flow of material and dust collection.

Elevator Belt

The elevator belt is designed to provide a secure and reliable connection between the buckets. It is also made from high-quality material that can withstand high temperatures, abrasions, and other wear and tear. Also, the belt features special features such as a high-strength splice that ensures uniform and reliable operation.

What Makes Us the Leading Bucket Elevator Manufacturer and Supplier

Prime is the leading manufacturer and supplier of bucket elevators and other related equipment. Our products are designed with durability, reliability, and efficiency in mind, which makes them a great choice for any application. With our bucket elevators, you can expect minimal maintenance requirements and unbeatable performance in even the most demanding environments.

The bucket elevators we offer feature minimal maintenance requirements due to their robust design and construction. They are specifically engineered to deliver reliable operation even in difficult environmental conditions without fail. Moreover, they require only minimal lubrication for optimal performance and smooth operation. In addition to this, our bucket elevators are also capable of handling a wide variety of materials, including food products, minerals and grains. This allows you to use them for many different applications across various industries both indoors and outdoors.

Our bucket elevator components come with a series of special features that ensure the highest level of reliability and durability. For instance, our head pulleys are designed to drive the elevator efficiently while also featuring adjustable tensioning mechanisms for easy chain or belt tension adjustments. The buckets we provide are made from durable materials that can withstand harsh elements as well as wear and tear over time.

Additionally, they feature drainage holes and other special features that allow for proper material flow while minimising dust accumulation within the system.

We also provide elevator belts made from high-strength materials that guarantee uniform and reliable operation over time. These belts feature additional features such as high-strength splice joints which not only provide added strength but also facilitate easy installation process by allowing users to customise them according to their specific needs. Furthermore, our bucket bolt sets secure the buckets firmly on the belt while offering simple installation even in difficult environments thanks to their robust construction material options we provide along with various sizes to choose from depending on the application at hand. Finally, our pulley slide lagging reduces friction between the buckets and drive belt significantly thus extending its lifespan substantially—this comes with a range of size options so you may get precisely what you need without having to compromise quality or safety in any way whatsoever!

At Prime we pride ourselves on being able to offer superior service that exceeds customer expectations by providing comprehensive pre-sale technical services along with after-sales support throughout a product’s life cycle. Our R&D team continuously works hard so we can provide customers with advanced technological solutions tailored specifically for their individual needs. We offer competitive prices on our products as well as excellent discounts for bulk orders or repeat customers through our loyalty program. Moreover, we provide quick delivery on all orders throughout the country so that customers can receive their items in no time at all! With all these advantages combined it’s no surprise why Prime has been chosen time again as the leading bucket elevator manufacturer and supplier in the industry!