Continuous Z/C Type Bucket Elevator

Transportation of Bulk Material

Handles various powders and bulk materials, especially in factories with limited space

Bucket Size

- 500 SPECs across 17 bucket types

Max capacity

- 10m³/h to 180m³/h

Our Regular Bucket Elevators

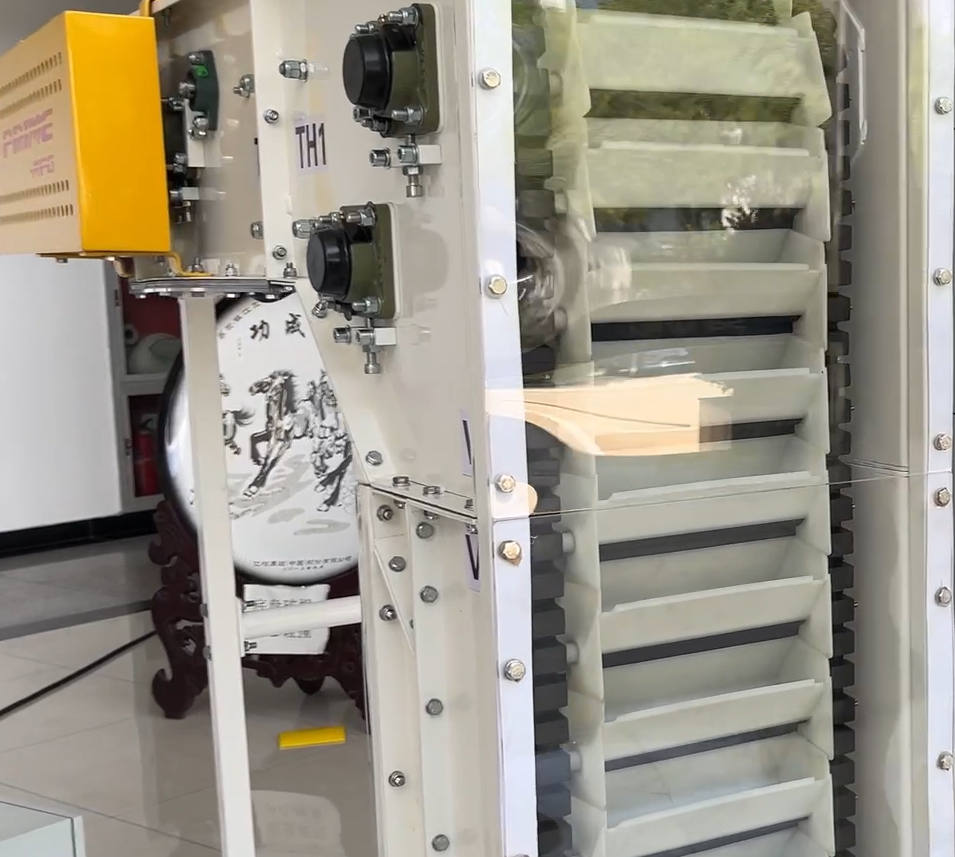

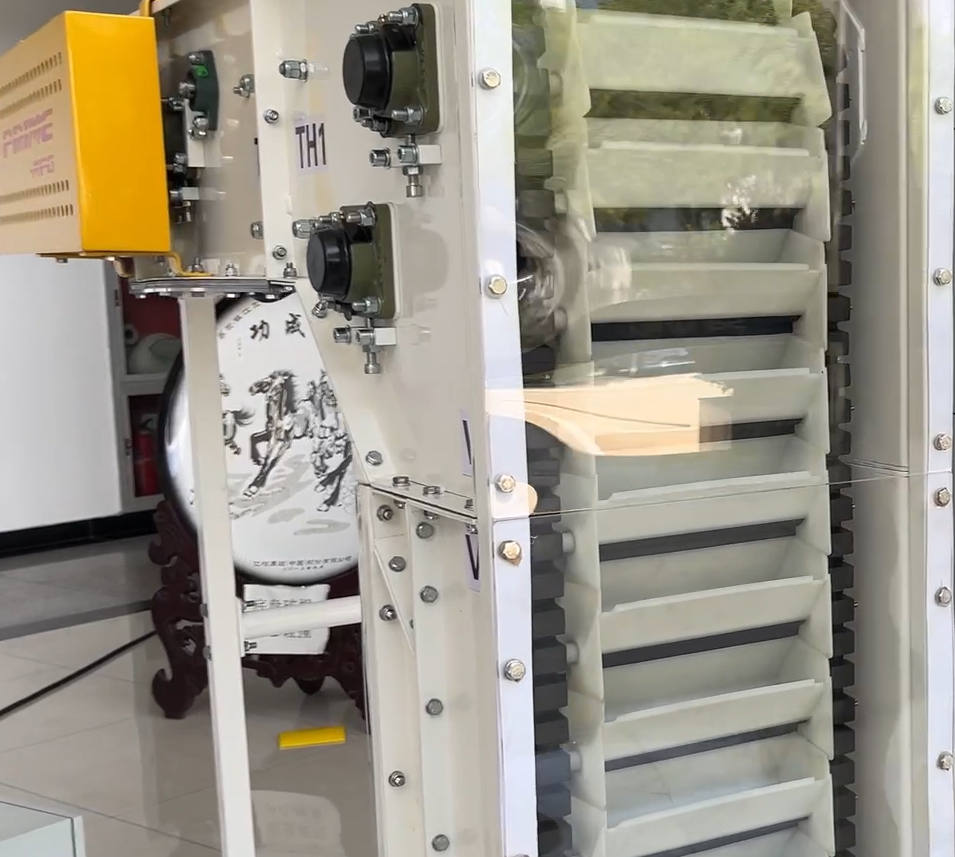

Z (C) Type Continuous Bucket Elevator

The elevator connects seamless buckets using a rubber chain with a steel wire core, forming a continuous and seamless horizontal and vertical transport system. It is suitable for handling various powders and bulk materials, especially in factories with limited space.

Gallery

Regular Bucket Elevator Features

Multi-Dimensional Transport Paths

Creates multi-dimensional transport paths without needing intermediate horizontal-to-vertical conversion devices. The material transport trajectory can be Z or C-shaped, offering flexibility to adapt to different factory layouts and needs.

High Transport Capacity

Capable of handling large volumes of material efficiently.

Low Maintenance Cost

The rubber chain does not require frequent tension adjustments or lubrication, resulting in low maintenance costs.

Durability and Long Lifespan

The rubber chain is wear-resistant and long-lasting, with noiseless operation ensuring a quiet environment. Small Footprint: Occupies relatively small space, making it ideal for factories with limited space.

Damage-Free Handling

Materials are gently loaded and unloaded by free fall, preserving integrity.

No Spillage

Ensures no spillage during loading and unloading, preventing waste and contamination.

Body Material

Reinforced Nylon, stainless steel. The company provides timely supply of wear parts and technical support through its systematic production base and Melbourne storage and processing center.

Note

For multi-point discharge or long horizontal transport distances in the upper section, consider using Prime's Z (C) Type Bucket Elevator.

Specifications

Available in various capacities to meet different transport needs, with a range from 10m³/h to 180m³/h.

Clean Discharge

Ensures complete unloading with no residue left behind.

Wash-Down Design

Easy to clean, preventing dust and debris accumulation, ideal for food processing and pharmaceutical industries.

The company has a production base for common system accessories and a storage and processing center located in Melbourne, providing timely supply of complete wear parts. Customized and system integration design are available.The company has a production base for common system accessories and a storage and processing center located in Melbourne, providing timely supply of complete wear parts.

Customized design and system integration design are available.

Rubber Chain Elevating

The rubber chain, unlike conventional rubber belt or steel chain, brings new and better characteristics of elevating. The new chain perform more quiet, robust, and more production.

Elevator Buckets

The buckets used in the bucket elevator are designed to be sturdy and reliable. They come in a variety of shapes, sizes and materials to suit different applications. Also, they can be customised according to the customer’s needs.

Bucket Bolt Sets

Bucket bolt sets are used to secure the buckets to the elevator belt. They come in a variety of sizes and materials, so that they can be used for different applications. Also, the installation of bucket bolt sets is simple and easy.