Conveyor Systems

Bulk material conveyors are specialized equipment designed for the continuous transportation of granular, powdery, or lumpy materials. They are widely used in industries such as mining, metallurgy, chemicals, grain, and building materials. Their efficiency,

reliability, and versatility make them essential equipment for material handling in various industries.

Utilizes a continuous belt as the traction and carrying component, suitable for horizontal or inclined transport of bulk materials. Features: Simple structure, long conveying distance, high conveying capacity, smooth operation, energy-saving and environmentally friendly, strong adaptability.

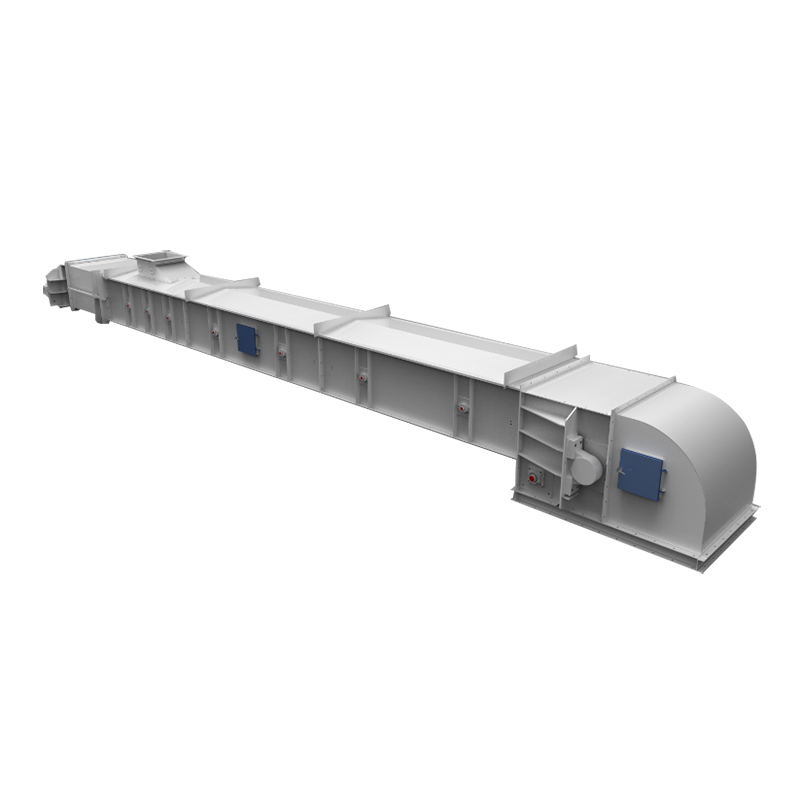

Uses a scraper chain to push bulk materials along a trough, suitable for agriculture and food processing, mining and coal industries. Features: Robust construction, high transport efficiency, versatile application, low material spillage, customizable design. Screw Conveyor

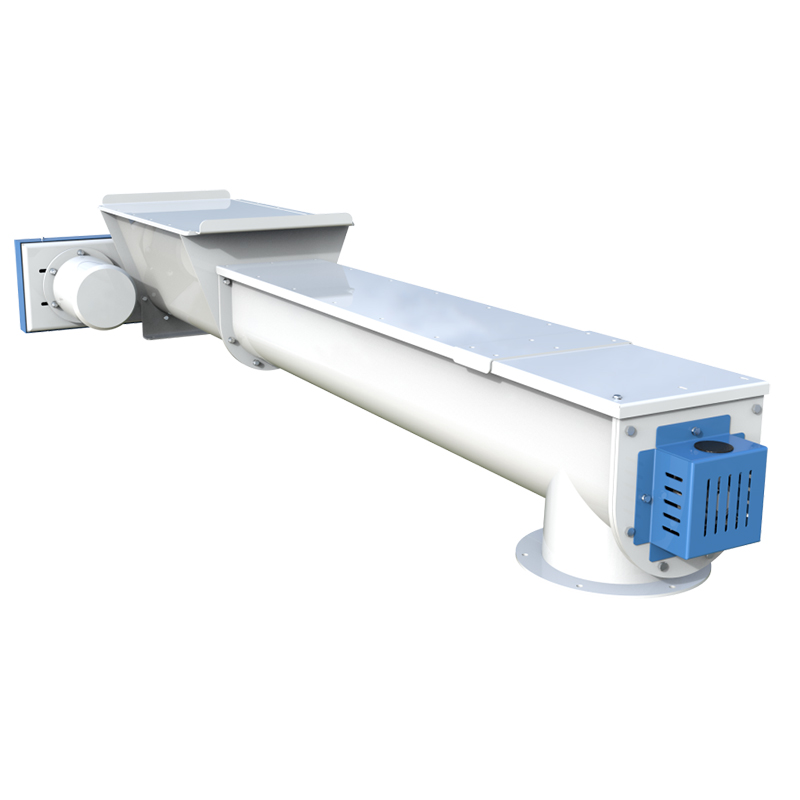

Uses a rotating helical screw blade to move materials, widely used in agriculture and food processing industries. Features: Compact structure, versatile material handling, precise feeding and discharging control, flexible configuration, low maintenance, customizable.

Conveyor Manufacturers Australia

Prime’s conveyors are designed to move materials or products from one location to another within a facility or production process. It is an integral part of material handling systems and plays a crucial role in various industries, including manufacturing, logistics, packaging, and mining. They come in different types and configurations to accommodate a wide range of materials, production requirements, and environmental conditions.

FLAT SURFACE CONVEYOR BELT

Designed to transport and move items or materials horizontally or with a slight incline. It is typically made of a flexible material, such as rubber, fabric, or plastic, and it rests on a flat surface or a series of rollers to support and guide the belt along its path.

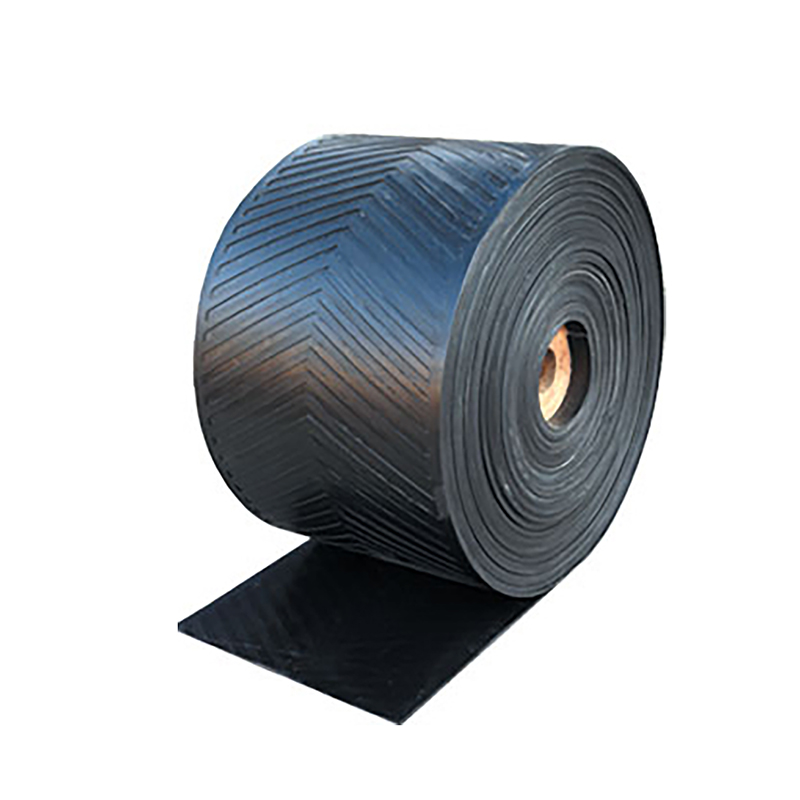

PATTERNED CONVEYOR BELT

Features a pattern of raised ribs or cleats on its surface. These patterns help improve the grip and stability of the belt, allowing it to efficiently convey materials up inclines or prevent items from slipping during transportation.

IMPACT BARS

The elevator belt is the most important component of a bucket elevator. It is designed to be strong and reliable, and it comes in a variety of sizes and materials so that it can handle different types of materials.

Rollers And Frames

Belt fasteners are used to secure the elevator belt to the frame. They come in a variety of sizes and materials, so that they can be used for different applications. Also, the installation of belt fasteners is simple and easy.

Conveyor Skirting

The pulley slide lagging is designed to reduce friction between the bucket elevator buckets and the drive belt. It also helps reduce wear on the pulleys, which can extend the life of the system. It is made from robust materials for durability. Also, it is available in a variety of sizes and materials.

Pulley Slide Lagging

Designed to improve traction and increase the grip between the pulley and the conveyor belt. It helps to prevent belt slippage, enhance belt tracking, and improve overall conveyor performance.

Bucket Elevator Features

Variable Speed Control

Prime’s conveyors offer adjustable speed controls, allowing operators to optimize the conveyor’s throughput based on the material being transported and the production needs. Variable speed control enables flexibility and enhances overall system efficiency.

Incline/Decline Capability

Prime’s conveyors are designed to handle inclines or declines, allowing for the movement of materials between different levels or elevations. This feature is particularly useful in applications where space is limited or when materials need to be conveyed uphill or downhill.

Reversible Operation

Prime’s conveyors conveyors have the ability to operate in both forward and reverse directions. Reversible operation enables flexibility in material handling, allowing for tasks such as sorting, diverting, or returning materials.

Accumulation Zones

Prime’s conveyors with accumulation zones incorporate sections where materials can temporarily accumulate without causing disruptions to the overall conveyor flow. This feature is useful in processes that require buffering or queuing of materials, preventing bottlenecks or overloading downstream operations.

Modular Design:

Prime’s conveyors feature a modular design, allowing for easy customization and expansion. Modular components can be easily configured and reconfigured to adapt to changing production requirements or to accommodate different layouts.

Safety Features

Prime’s conveyors are equipped with various safety features to protect operators and prevent accidents. These features may include emergency stop switches, safety guards, safety interlocks, and sensors to detect blockages or abnormalities in the conveyor operation.