Patterned Conveyor Belt

Commonly used in

Industrial & Manufacturing

Consumer Packaged Goods

Food & Beverage

PATTERNED CONVEYOR BELT

Find the solution that best fits your application

Our Patterned Conveyor Belt

Suitable to convey materials such as powder, granules as well as packaged materials at angleless than 40 degrees.

BELT TYPES

The belts include general use, oil-resistant, acid-alkali resistant, cold-resistant, static conductive, fire retardant, wear-resistant and heat resistant types etc.

TECHNICAL DATA

Standard: In accordance with ISO/FDIS 14890:1999

Features

- The carcass can be made from Polyester EP, Nylon NN, Cotton CC, and Polyester Cotton TC;

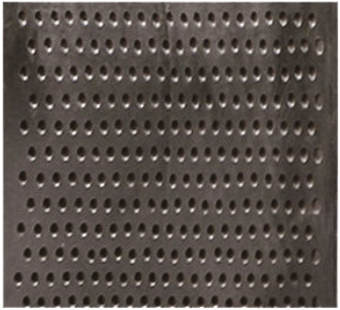

- Patterned Belt includes various patterns such as “Cross”, “V”, “Doted”, “Crescent”, etc.

- Suitable for incline conveying.

Specifications

Excluding the pattern measurements, the overall belt specifications and rubber cover properties of the patterned conveyor belt remain the same as the flat surface conveyor belt under the condition of the same carcass and rubber cover materials.

Patterned Conveyor Belts

Patterned Conveyor Belts

Grip-Enhanced. Slippage-Resistant. Ideal for Inclines.

Prime Manufacturing’s patterned conveyor belts are engineered to move materials securely on steep angles, wet conditions, or high-friction surfaces. Designed with a variety of surface profiles, these belts deliver improved traction without compromising belt flexibility

Our patterned conveyor belts are designed for transporting bulk and packaged materials such as powders and granules—on inclined surfaces up to 40°. The surface profiles ensure reliable grip and material stability during movement.

Key Benefits

Pattern Options

Chevron, herringbone, and diamond-top textures available for different load types and incline levels.

High Wear Resistance

Built to withstand abrasion, oils, and weather exposure in tough environments.

Custom Lengths & Widths

Tailored to fit your existing conveyor system for seamless replacement.

Gallery

Specification

Standard

Conforms to ISO/FDIS 14890:1999

Carcass Materials

Polyester (EP), Nylon (NN), Cotton (CC), Polyester-Cotton (TC)

Pattern Options

V-shape, Crescent, Cross, Dotted and more—ideal for incline conveying

Belt Specifications

Excluding the pattern measurements, the overall belt specifications and rubber cover properties of the patterned conveyor belt remain the same as the flat surface conveyor belt under the condition of the same carcass and rubber cover materials.

Available Belt Grades

- General Purpose

- Oil-Resistant

- Acid & Alkali-Resistant

- Cold-Resistant

- Static-Conductive

- Flame Retardant

- Wear & Heat Resistant

Why Choose Prime?

- Engineered for agriculture, mining, and industrial conveyors

- Anti-slip performance on steep inclines

- Quick supply from local inventory

- Technical support for pattern selection

Elevator Bucket — Engineered for Superior Performance

Optimized Compatibility

Designed to work seamlessly with leading elevator brands, delivering improved lifting speeds and greater material capacity.

Advanced Material Formula

Manufactured using a proprietary blend that ensures long-lasting durability and consistent performance in heavy-duty environments.

Airflow-Efficient Design

Features a strategically placed bottom opening to enhance airflow and minimize material backflow, promoting smoother and more efficient discharge.