Continuous Screw Flights

Commonly used in

Industrial & Manufacturing

Consumer Packaged Goods

Food & Beverage

CONTINUOUS SCREW FLIGHTS WITH THICK OUTER EDGE

Find the solution that best fits your application

Our Continuous Screw Flights With Thick Outer Edge

Material: Carbon/Mild Steel, Alloy Steel, Stainless Steel.

Features

- High precision manufacturing process.

Gallery

-

Short production time, excellent overall rigidity and strength.

-

Easy to weld and assemble.

-

Although outer edge thickness is about 1/2 of inner edge thickness, the hardness of outer edge is almost doubled after cold rolled process there for it is much more wear-resistant than inner edge.

Continuous Screw Flights

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Our Product

Prime MFG’s Continuous Screw Flights with Thick Outer Edge are engineered for high-wear and abrasive material handling applications. The reinforced outer edge significantly increases durability and reduces the rate of flight thinning, making them ideal for industries dealing with sand, cement, aggregates, and other highly abrasive bulk materials. Cold-rolled and precisely formed, these flights deliver reliable conveying with extended operational life, even in the harshest environments.

FEATURE

- Reinforced thickened outer edge for extended wear life

- Cold-rolled continuous helix design ensures smooth material flow

- Ideal for high-abrasion applications such as sand, ash, cement, or gravel

- Available in carbon steel, stainless steel, and wear-resistant alloy options

- Custom outer thickness, pitch, and flight diameter upon request

- Compatible with standard and custom screw conveyor configurations

- Reduces maintenance frequency and downtime in wear-critical operations

Why Choose

Thickened Outer Edge

Increased edge thickness improves resistance to wear and erosion in aggressive conveying environments

High-Wear Applications

Perfect for cement, sand, gravel, fly ash, and other abrasive bulk materials

Material Options

Manufactured in mild steel, stainless steel, or hardened wear-resistant alloys based on your needs

Custom Dimensions Available

Tailored pitch, diameter, shaft size, and outer edge thickness for system-specific requirements

Cold-Rolled Forming

Single continuous spiral with consistent flight profile ensures uninterrupted material flow and reduced buildupDesigned to work seamlessly with drop forged, drag link, and round link chains in bulk material handling

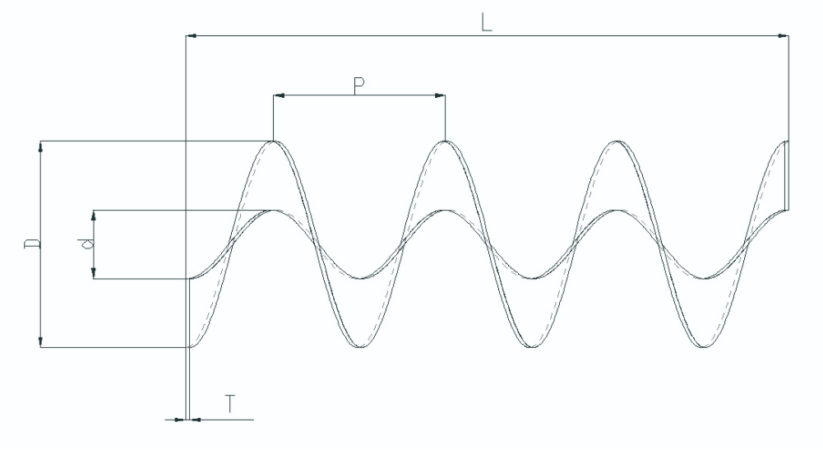

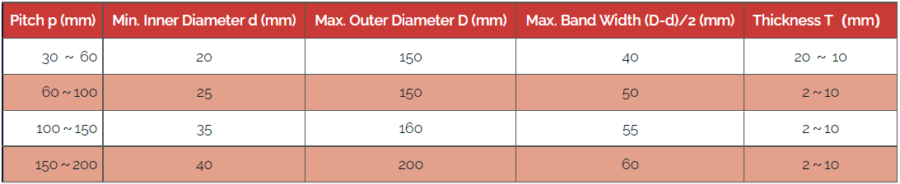

Specifications