Pulley Slide Lagging

Commonly used in

Industrial & Manufacturing

Consumer Packaged Goods

Food & Beverage

PULLEY SLIDE LAGGING

Find the solution that best fits your application

Features

Superior Traction: The diamond shape and Z shape groove on the surface greatly increases the friction/traction between the pulley and belt. Therefore, less slipping and better driving performance.

Superior Traction: The diamond shape and Z shape groove on the surface greatly increases the friction/traction between the pulley and belt. Therefore, less slipping and better driving performance.

- Self-Cleaning: Foreign matter discharges itself through the double chevron groove on the pulley lagging surface and the gap between laggings. This structure ensures no material build-up so that the belt is easy to track and runs steady. Protect the pulley face and belt cover from damage and increase the service life.

Self-Cooling: The ventilation and heat dissipation improved through the double chevron groove on the pulley lagging surface and the gap between laggings. The reduced temperature of both belt cover and pulley face results in better performance and longer life.

Broad application range: Can be fitted in all types of the pulley with different diameters as long as the static balance is reached.

Selection of materials: Two types of materials are available to choose from: (1) General Purpose: High-elasticity, abrasion-resistant, oil-resistant, anti-static material which is widely used for grain handling and other general purposes. (2) Flame Retardant Type: High abrasion resistant, flame retardant, oil-resistant and anti-static. Meet the safety requirements of the underground mining industry.

Easy to maintain: Replace the slide lagging without removing the pulley from the conveyor system and extra rubber fabricating. Simply slide out the old lagging, slide in new lagging and resume operation. Reduce the shutdown time and maintenance cost dramatically and translate into high productivity

Gallery

Maximize Grip. Minimize Downtime. Built to Slide In.

Prime Manufacturing’s pulley slide lagging is engineered for fast installation, excellent wear resistance, and superior traction. Designed for belt conveyor systems handling bulk materials, our lagging ensures longer pulley life and improved system efficiency

Key Benefits

Slide-On Design

No hot vulcanization required—replace lagging in minutes, not hours.

High-Grade Materials

Made from durable rubber or ceramic for maximum friction and wear life

Custom Sizing

Available in various widths and thicknesses to fit standard pulley types.

Enhanced Traction

Our diamond and Z-groove surface profiles deliver maximum grip between the pulley and belt, significantly reducing slippage and boosting power transmission efficiency

Long Service Life

Made from high-elasticity, wear-resistant rubber, and secured with a reliable locking system, our lagging is built to withstand demanding conditions and extend drum life

Self-Cleaning Design

Double chevron grooves and spacing between lagging sections help discharge debris naturally—keeping the belt clean, aligned, and running smoothly with reduced wear.

Thermal Efficiency

The grooved structure improves airflow for natural cooling. This helps reduce heat build-up on both the belt cover and pulley face, increasing operational lifespan

Wide Compatibility

Designed to fit pulleys of all diameters, provided the system is statically balanced—making it ideal across industries and conveyor setups

Effortless Maintenance

No need to dismantle the pulley—just slide out the worn lagging and replace with new. Quick swaps translate to shorter downtimes and lower maintenance costs

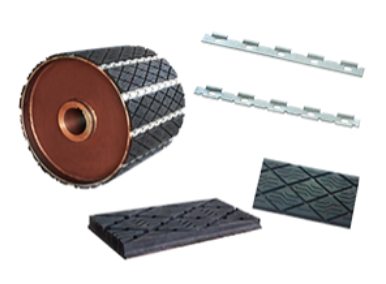

Parts for Pulley Lagging

Pulley Diameter Calculation (Without Lagging)

To determine your base pulley diameter, subtract twice the lagging pad thickness (H) from the total designed diameter with lagging

Complete Lagging Setups

Our engineering team can recommend a balanced pulley lagging configuration based on your pulley’s core diameter and operational face length. Custom dimensions and design preferences can also be accommodated

Specifications

Superior Traction: The diamond shape and Z shape groove on the surface greatly increases the friction/traction between the pulley and belt. Therefore, less slipping and better driving performance.

Superior Traction: The diamond shape and Z shape groove on the surface greatly increases the friction/traction between the pulley and belt. Therefore, less slipping and better driving performance.

- Self-Cleaning: Foreign matter discharges itself through the double chevron groove on the pulley lagging surface and the gap between laggings. This structure ensures no material build-up so that the belt is easy to track and runs steady. Protect the pulley face and belt cover from damage and increase the service life.

Self-Cooling: The ventilation and heat dissipation improved through the double chevron groove on the pulley lagging surface and the gap between laggings. The reduced temperature of both belt cover and pulley face results in better performance and longer life.

Broad application range: Can be fitted in all types of the pulley with different diameters as long as the static balance is reached.

Selection of materials: Two types of materials are available to choose from: (1) General Purpose: High-elasticity, abrasion-resistant, oil-resistant, anti-static material which is widely used for grain handling and other general purposes. (2) Flame Retardant Type: High abrasion resistant, flame retardant, oil-resistant and anti-static. Meet the safety requirements of the underground mining industry.

Easy to maintain: Replace the slide lagging without removing the pulley from the conveyor system and extra rubber fabricating. Simply slide out the old lagging, slide in new lagging and resume operation. Reduce the shutdown time and maintenance cost dramatically and translate into high productivity

Choosing the Right Lagging Pad

- For drum-face pulleys, use SRS15 or SRS19 pads.

- For flat-face pulleys under 750 mm, the center section can be thickened to allow SRS15 or SRS19 usage

- For flat-face pulleys over 750 mm, a combination of SRE19 + SRS19 + SRE19 achieves a drum profile for optimal performance

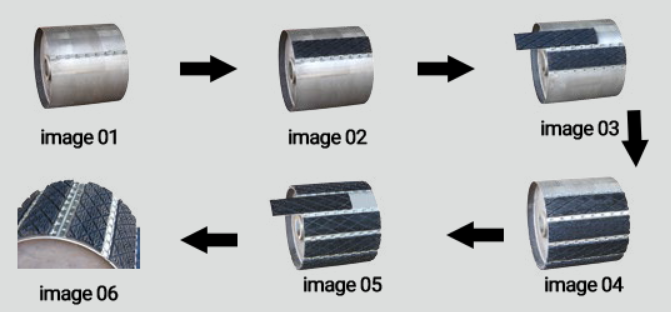

Installation Step

- Based on the number of lagging pads required, mark the installation positions of the lagging pads on the pulley evenly

- Weld or bolt the first retainer onto the marked position (make sure the retainer is parallel to the axial line of the pulley). See image 1

- Slide the lagging pad into the first installed retainer, and then based on the corresponding position, weld or bolt the second retainer on the other side of the pad. Repeat this step until installing all retainers and pads. See image 2, 3, 4

- After installing the pad into the retainer, please also install two fixtures at both ends of the pads to prevent the pads from sliding out of the retainer

- The single retainer fixing installation should follow the spacing between adjacent single retainers. See image 5

- Maintenance/Replacement: Remove the fixtures on both ends of the pads. Simply slide out the old ones and slide into the new ones, then put the fixtures back on again. See image 6