PLASTIC FLIGHT ATTACHEMENT

Find the solution that best fits your application

Our Pastic Flight Attachement

Local CNC machining capability for a quick response time of customer design.

Material: UHMWPE

Gallery

Rubber Elevator Belts

Durable rubber elevator belts engineered for bulk handling, food-grade use, and oil-resistant, antistatic performance.

Our Product

At Prime MFG, our Rubber Elevator Belts are built to handle demanding material handling applications across agriculture, food processing, mining, and industrial environments. Designed with a high-strength, low-stretch Terylene fabric carcass and formulated rubber cover, our belts deliver durability, flexibility, and resistance to oil and static build-up.

Whether you’re transporting grains, pellets, powders, or abrasive materials, Prime MFG’s rubber elevator belts ensure reliable vertical conveying with minimal wear and tear. We also offer custom configurations with punched mounting holes for easy installation.

FEATURES OF THE PRODUCT

- High-tensile Terylene carcass for minimal stretch and improved load-bearing capacity.

- Oil-resistant and antistatic rubber compound for enhanced safety and performance.

- Custom hole punching for precise bucket spacing and easy installation.

- Compatible with a wide range of bucket elevator systems.

- Excellent adhesion between carcass and rubber for long service life.

- Optional food-grade rubber covers for grain and food processing use.

Why Choose

Carcass Material

Constructed with dipped Terylene fabric offering dimensional stability and high breaking strength.

Belt Width Range

Available in various standard and custom widths to suit your elevator configuration.

Oil Resistance

Special rubber formulation resists oil exposure, extending belt life in greasy environments.

Antistatic Design

Built-in antistatic properties help discharge static electricity, ideal for dry bulk materials.

Custom Hole Punching

Belts can be pre-punched to match your bucket layout, reducing on-site preparation time.

Food Grade Option

Food-safe rubber covers are available for hygienic applications in grain and food handling systems.

Specifications

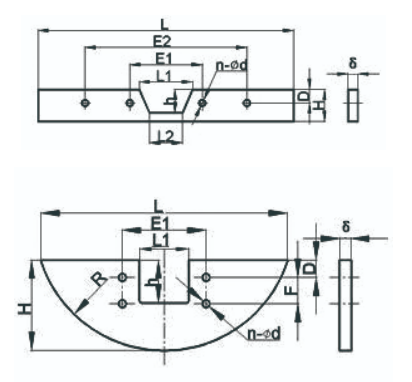

Examples of drag UHMW flight

FAQ

They’re suitable for agriculture, mining, food processing, bulk solids, and grain handling.

Yes, we offer custom punching services as per your bucket spacing and elevator design.

Absolutely. We offer food-grade variants with safe rubber coatings for grain and edible materials.

With proper installation and load matching, they deliver long service life even in harsh environments.

Yes, we provide belts in standard and made-to-order dimensions tailored to your setup.