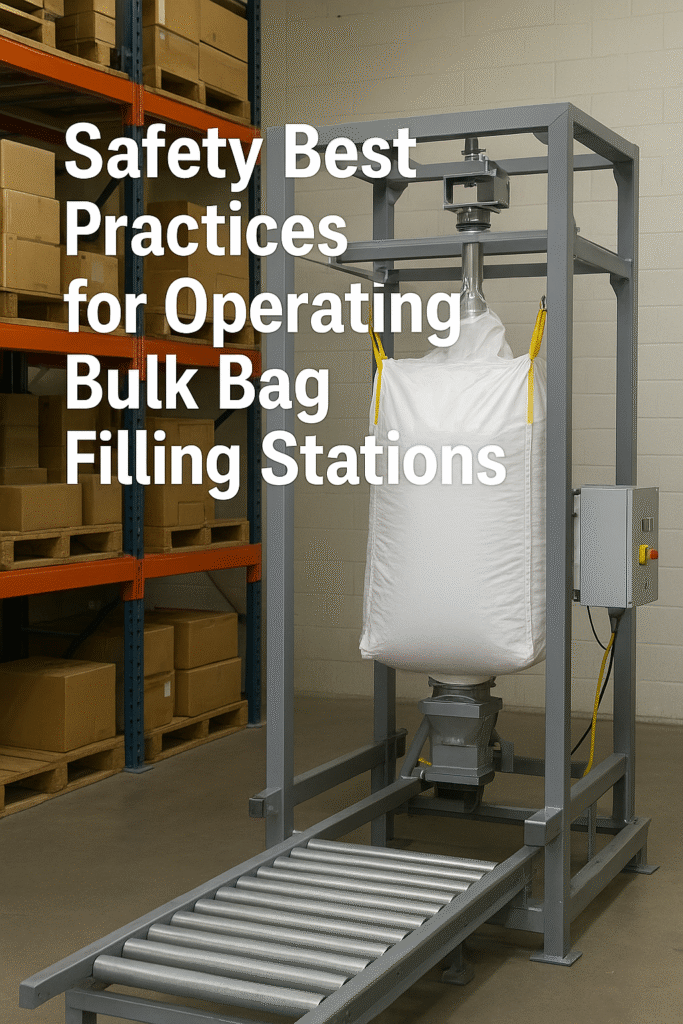

Bulk bag filling stations are crucial in handling powders, grains, chemicals, and other loose materials. However, without proper safety measures, they can pose hazards. Implementing best practices ensures efficient operation while safeguarding the team.

At Prime Manufacturing, we offer tailored bulk bag filling stations designed with safety and efficiency in mind. Here are several safety best practices to follow:

- Proper Operator Training

Ensure all operators are trained to understand equipment functionality and emergency protocols. - Use Personal Protective Equipment (PPE)

Employees should wear dust masks, gloves, and safety goggles to protect against airborne particles and material splashes. - Secure the Bag Properly

Ensure bulk bags are attached firmly using hooks or straps to prevent sudden detachment. - Check for Blockages

Regularly inspect the filling spout to prevent clogging, which could cause material spills or equipment damage. - Follow Load Capacity Guidelines

Never exceed the recommended weight capacity. Overloading could lead to bag rupture, equipment failure, or injuries.

Adopting a reliable bulk bag filling system from Prime Manufacturing not only improves throughput but also ensures your operators are working in a safe environment.