Sectional Screw Flights

Commonly used in

Industrial & Manufacturing

Consumer Packaged Goods

Food & Beverage

SECTIONAL SCREW FLIGHTS

Find the solution that best fits your application

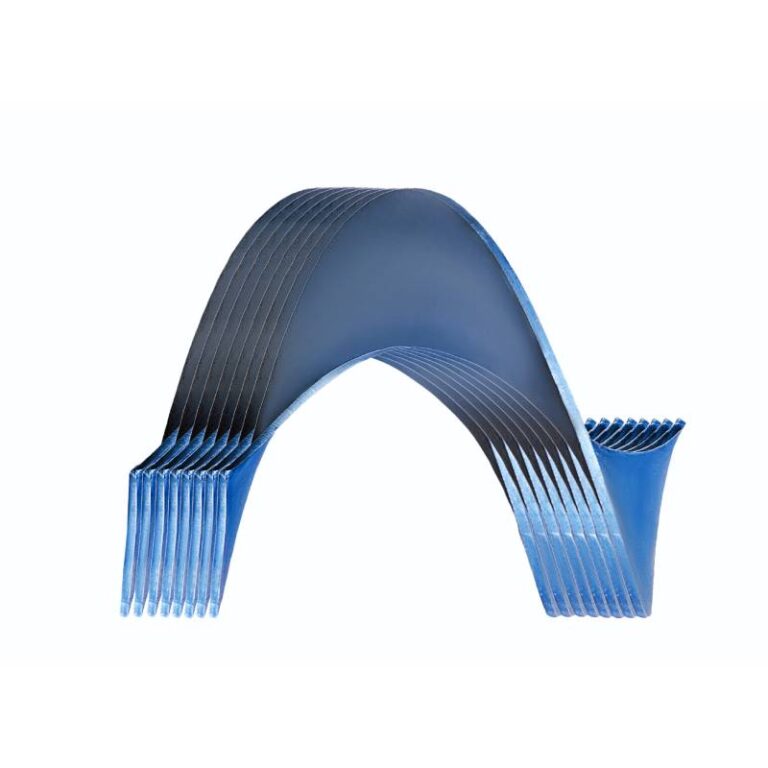

Our Sectional Screw Flights

Material: Carbon/Mild Steel, Alloy Steel, Abrasion-resistant Steel, Stainless Steel.

Features

Our patented manufacturing process can meet special requirements such as forming various materials, wide thickness range, large diameters, ribbon, and tapered or variable pitch flights. Flights can also be hard-faced or coated with wear-resistant materials.

Every sectional screw flight is produced in single pitch length with high precision consistent thickness between inner and outer edges.

Customization available upon request.

Gallery

Sectional Screw Flights

Our Product

Prime MFG’s Sectional Screw Flights are custom-fabricated individual flight segments designed to suit a wide variety of conveying applications. Manufactured using a precision forming process, each flight is produced to exact pitch, thickness, and diameter specifications—ideal for demanding industrial setups including mixing, feeding, and inclined conveying systems. Whether you need ribbon flights, tapered flights, or variable pitch configurations, our sectional flights offer strength, consistency, and exceptional wear resistance across all materials

FEATURE

- Manufactured to exact pitch, thickness, and diameter requirements

- Available in carbon steel, alloy steel, stainless steel, and abrasion-resistant grades

- High consistency between inner and outer edges for balanced operation

- Ideal for variable pitch, tapered, or ribbon flight configurations

- Flights can be hard-faced or coated for extended wear life

- Suitable for feeders, conveyors, mixers, and press augers

- Tailor-made for OEM systems and custom equipment retrofits

Why Choose

Custom Formed Designs

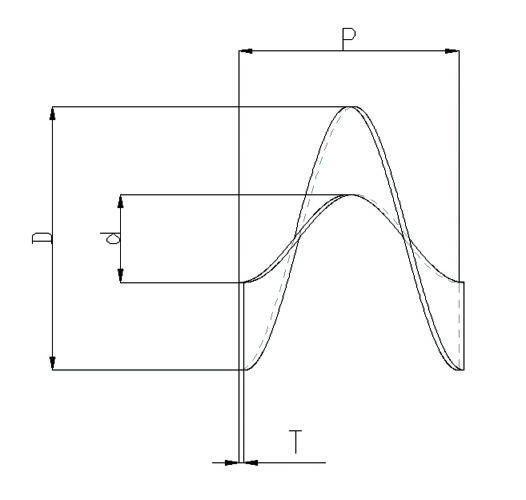

Built to exact dimensions with pitch, OD, ID, and thickness tailored to your system’s performance needs

Wide Material Selection

Offered in carbon steel, stainless steel, alloy steel, and wear-resistant materials for all environments

Advanced Manufacturing

Produced using precision-forming techniques that allow tapered, ribbon, variable pitch, or thick flights

Balanced Wear & Performance

Uniform thickness across inner and outer edges ensures longer life and reduced vibration during operation

Wear Coating Options

Optional hard-facing or protective coating to extend the life of flights in highly abrasive applications

OEM & Custom Compatibility

Engineered for integration into both OEM systems and unique industrial processes requiring non-standard configurations

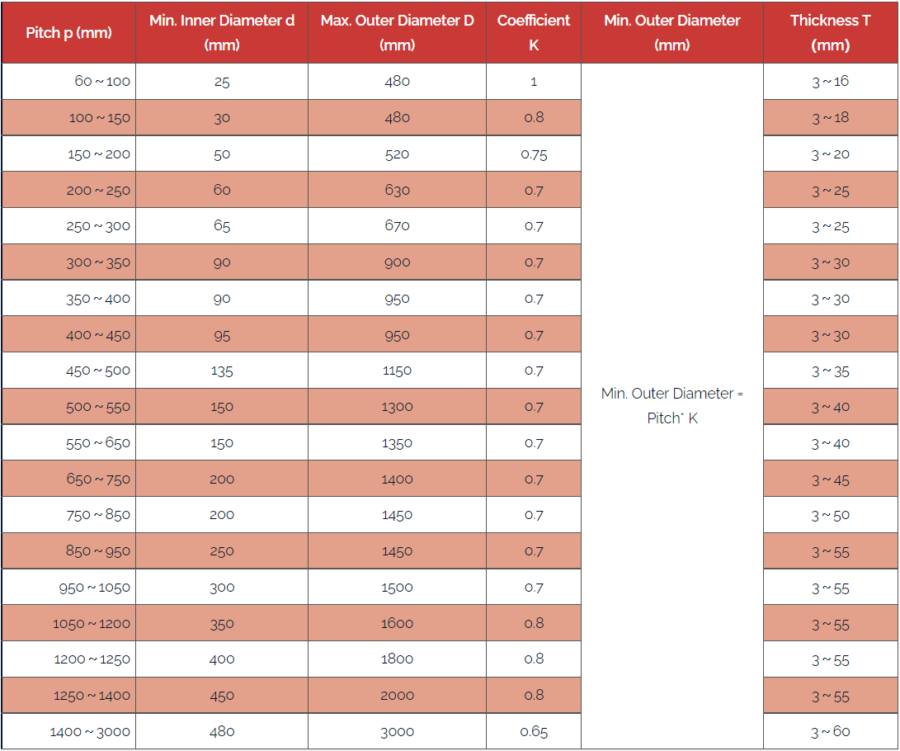

Specifications

Note:

1. If the thickness is in the range of 20mm to 30mm, bandwidth (OD-ID)/2 ≤ 400mm.

2. If the thickness is in the range of 30mm to 40mm, band width (OD-ID)/2 ≤ 370mm.

3. If the thickness is in the range of 40mm to 50mm, band width (OD-ID)/2 ≤ 350mm.

4. If the thickness is in the range of 50mm to 60mm, band width (OD-ID)/2 ≤ 320mm.

FAQ

Sectional flights are individual segments formed from flat steel and ideal for custom configurations. Continuous flights are formed from a single piece and are more suited for uniform pitch requirements.

Yes, our manufacturing process supports the production of ribbon, tapered, variable pitch, and even left- or right-hand flights.

We offer carbon/mild steel, stainless steel, alloy steel, and hardened abrasion-resistant steel, with optional wear coatings.